Technology

An Enterprise Aiming for a Lot Bigger Tomorrow, WONCHEUN

Product Process

WONCHEUN’s Specialized Technical Skills, Process Construction & Development

WONCHEUN is operating an elaborate management system after being equipped with specialized process from Stage 1 to Stage 10, and endlessly endeavoring for efficient production management through quality control, R&D and manufacturing automation system.

-

Manufacturing business + ICTSmall quantity batch production,

Work Efficiency -

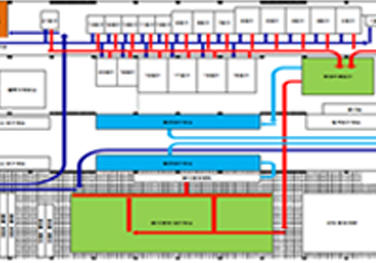

POP System ConstructionVisible Production

Management -

Mold DevelopmentPrecision Processing

Root Technology -

Unmanned Inspection SystemAutomated Vision Inspection

-

Customer ImpressionReliability Securing

Process of Product Process

-

01Obtaining Orders for Mold

-Receipt of a Customized Plan

-Set up a Plan within less than 7 days

-Submission of a Quotation

-

02Manufacturing Review

-Self Review of Modeling

-Reflection of a Problem & Development

-

03Mold Design

-Final Approval through

a Customer’s Confirmation-Design Progress in line with Modeling

-

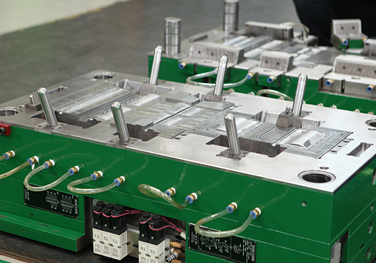

04Mold Manufacturing

-Integration of WONCHEUN’s

own know-how-Precise Mold Processing

& Manufacturing -

05Preparation for Test Injection

Preparations such as raw materials warehousing, inspection,

Autofeeding system, drying,

moisture measurement, and mold preheating, etc. -

06Test Injection

-Progress of super-precision

Mold Test-eview of mass production

property, problems in a product and mold, and confirmation of product consistency in comparison with drawings, etc. -

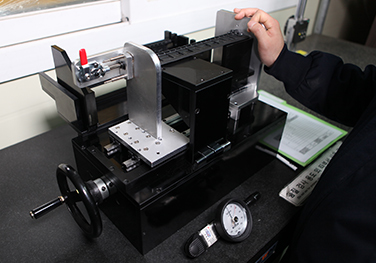

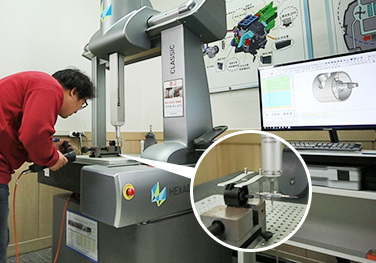

07Precision Measurement

-Use of precision measurement tools, such as a 3-dimensional measuring instrument, micrometer, vernier,

and height gauge, etc.-Data Processing

-Issue of Precision Measurement Acceptance Report

-

08PPAP Document Registration

-PPAP document registration and approval of mass production

-submission of a customer’s documents, standby status for mass production

-

09Product Approval

-Completion of a customer’s Reliability Test Approval

-Conversion to Mass Production

-Maintenance of the Mass Production System until the product is discontinued

-

10Packaging/Transportation

-Packaging specifications set-up

-Total inspection and packaging

-Continuance for 100 days, Control of poor quality occurrence

-Delivery packaging through 3.5-ton, and 5-ton vehicles

-

01Obtaining Orders for Mold

Receipt of a Customized Plan

Set up a Plan within less than 7 days

Submission of a Quotation

-

02Manufacturing Review

Self Review of Modeling

Reflection of a Problem & Development

-

03Mold Design

Final Approval through

a Customer’s ConfirmationDesign Progress in line with Modeling

-

04Mold Manufacturing

Integration of WONCHEUN’s

own know-howPrecise Mold Processing

& Manufacturing -

05Preparation for Test Injection

Preparations such as raw materials warehousing, inspection,

Autofeeding system, drying,

moisture measurement, and mold preheating, etc. -

06Test Injection

Progress of super-precision

Mold Testeview of mass production

property, problems in a product and mold, and confirmation of product consistency in comparison with drawings, etc. -

07Precision Measurement

Use of precision measurement tools, such as a 3-dimensional measuring instrument, micrometer, vernier,

and height gauge, etc.Data Processing

Issue of Precision Measurement Acceptance Report

-

08PPAP Document Registration

PPAP document registration and approval of mass production

submission of a customer’s documents, standby status for mass production

-

09Product Approval

Completion of a customer’s Reliability Test Approval

Conversion to Mass Production

Maintenance of the Mass Production System until the product is discontinued

-

10Packaging/Transportation

Packaging specifications set-up

Total inspection and packaging

Continuance for 100 days, Control of poor quality occurrence

Delivery packaging through 3.5-ton, and 5-ton vehicles

This company’s super-precision product production is in pursuit of 100% completion through quality control standards arranged by each process, and Spec control by the skilled specialized workforce, and supplying only the good quality products to a client company through the introduction of reliability improvement equipment.

-

Measurement of moisture in raw materials

Measurement of moisture in raw materials -

Verification of product assembly property

Verification of product assembly property -

Analysis of Measurement Data

Analysis of Measurement Data

WONCHEUN Co.,Ltd. is taking painstaking care of all process from order acceptance to delivery of products, and challenging to more reasonable manufacturing process construction and high-quality product cultivation through its ceaseless R&D.

-

Examination of mold structure

Examination of mold structure -

High-quality mold cultivation

High-quality mold cultivation -

Optimum manufacturing process construction

Optimum manufacturing process construction

WONCHEUN Co.,Ltd. has secured quality stability through automation construction in line with functional small logistics characteristics in need of high quality, and retained know-how required for double injection production, on the basis of which, this company is proceeding with double injection new technology development.

-

Raw Materials AUTO FEEDING SYSTEM

Raw Materials AUTO FEEDING SYSTEM -

Injection Automation Line

Injection Automation Line -

Storage warehouse of finished products

Storage warehouse of finished products